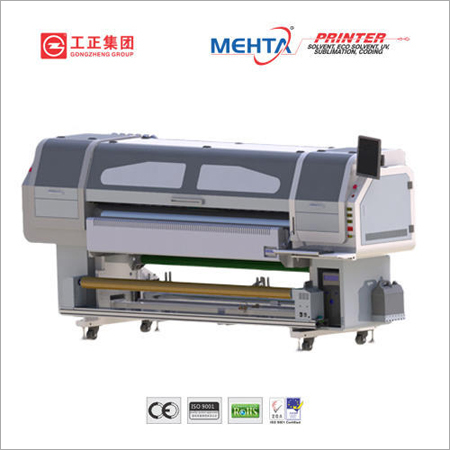

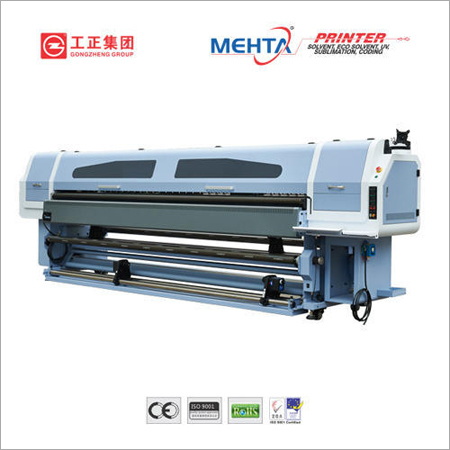

Solvent Printer Machine Starfire GZM 3202 Plus

Price 1800000.00 INR/ Unit

Solvent Printer Machine Starfire GZM 3202 Plus Specification

- Working Temperature

- 15C - 30C

- Features

- High-speed Starfire print heads, robust steel structure, intelligent drying system, auto cleaning

- Usage & Applications

- Billboards, banners, flex, vinyl printing, advertising graphics

- Processor Speed

- 1.2 GHz

- Cabinet Material

- Powder-coated reinforced steel

- Print Speed

- Up to 240 sqm/h

- Interface

- USB 2.0 / Network

- Humidity %

- 35% - 65%

- Function

- Outdoor & indoor signage printing

- Print Technology

- Piezoelectric drop-on-demand inkjet

- Power Supply

- Single phase AC 220V 10%

- Noise Level

- 60 dB

- Capacity

- Up to 3.2 meters print width

- Processor Type

- Industrial-grade high-speed processor

- Weight

- 520 kg

- Condition

- New

- Material

- Steel frame and aluminum components

- Dimensions

- 4560 mm x 900 mm x 1310 mm

- Gross Power

- 1850W

- Voltage

- AC 220V 10%, 50/60Hz

- Automatic Grade

- Automatic

- Color Print Speed

- 180 sqm/h (2 heads), 240 sqm/h (4 heads)

- Black Print Speed

- 240 sqm/h

- Maximum Paper Size

- 3200 mm

- Maximum Resolution

- 720 x 1440 dpi

- Use

- Large format solvent printing

- Voltage Range

- AC 220V 10%

- Display

- LED status display

- Media Handling

- Automatic feed and take-up system

- RIP Software Support

- Yes

- Ink Type

- Solvent-based ink

- Number of Print Heads

- 2 or 4 (configurable)

- Safety Systems

- Overheat protection, emergency stop

- Ink Supply System

- Negative pressure, continuous supply

- Software Compatibility

- Maintop / Photoprint / Caldera / Wasatch

- Language Support

- English + Multi-language

- Drying System

- Intelligent integrated IR & fan drying

- Print Head Type

- Starfire SG1024 Industrial Heads

Solvent Printer Machine Starfire GZM 3202 Plus Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1 Months

About Solvent Printer Machine Starfire GZM 3202 Plus

Product details

| Media Type | Flex |

| Brand/Make | Mehta |

| Power | 240 |

| Weight | 1115Kg |

| Ink Type | Solvent/Eco Solvent |

| Type | Digital printer |

| Automation Grade | Automatic |

| Heads | Starfire |

| Print Head | Starfire |

Technical Specification

| Item | Specifications |

| Model | GZM 3204SG |

| Print Head | 4 Starfire 1024 (25pl) |

| Ink | C.M.Y.K solvent/eco-solvent |

| Ink supply system | Negative Pressure Recirculation System |

| Printing width | Max. 3200mm |

| Media Type | Banner, Frontlit, Backlit, Vinyl, Film... |

| Feeding system | Automatic media feeding and taking up system with pneumatic shaft |

| Drying system | Pre, mid, post and extended heater + smart IR drying system |

| Speed | 300x400dpi 229m /h 300x400dpi 126m /h |

| Brand/Make | 2 600x400dpi 177m /h 600x400dpi 97m /h |

| Power | 2 300x600dpi 164m /h 300x600dpi 87m /h |

| Weight | 2 600x600dpi 125m /h 600x600dpi 65m /h |

| Ink Type | 2 300x800dpi 128m /h 300x800dpi 68m /h |

| Type | 2 600x800dpi 97m /h 600x800dpi 51m /h |

| Data Interface | External : USB2.0+; Internal: High-speed SCSI |

| Working Environment | Temp.23~29, Humidity:50%~80% |

| Software | Onyx+GZ control console |

| Power | 50Hz/AC,220V+10% 3A(printer)+10A(IR drying system) |

| Installed/Package Size | LxWxH(mm): 4660x960x1250 / 4930x1550x1690 |

| G.W./N.W. | 1345kgs / 1115kgs |

High Speed and Precision Printing

Equipped with Starfire SG1024 industrial print heads, the GZM 3202 Plus achieves rapid, precise prints with maximum speeds of 240 sqm/h and resolutions up to 720 x 1440 dpi. Whether using two or four heads, users can choose a configuration best suited for their production needs, maximizing output without sacrificing quality.

Advanced Drying and Media Handling

The printer integrates intelligent IR and fan drying systems, ensuring optimal ink curing. Its automatic feed and take-up system streamlines workflow, allowing for uninterrupted printing on materials up to 3.2 meters wide. These features reduce labor and minimize downtime during long print jobs.

Comprehensive Software and Safety Integration

Compatibility with industry-standard RIP software, including Maintop, Photoprint, Caldera, and Wasatch, enables easy integration into existing production environments. Multi-language support, LED status display, overheat protection, and emergency stop features safeguard both operators and equipment during operation.

FAQs of Solvent Printer Machine Starfire GZM 3202 Plus:

Q: How does the automatic feed and take-up system benefit printing operations?

A: The automatic feed and take-up system ensures continuous and consistent material handling, reducing manual intervention. It streamlines workflow, enhances efficiency, and minimizes the risk of media misalignment during long print runs, especially on wide-format jobs.Q: What is the process for configuring the number of print heads on the Starfire GZM 3202 Plus?

A: The Starfire GZM 3202 Plus allows users to select either two or four Starfire SG1024 print heads during purchase or installation. This configuration determines the print speed and productivity, enabling tailored performance for varying workload requirements.Q: Where is the GZM 3202 Plus typically used?

A: This solvent printer is ideal for both indoor and outdoor large-format signage applications, such as billboards, banners, flex, and vinyl advertising graphics. Its robust construction and versatile design cater to high-demand settings like print shops, advertising agencies, and sign manufacturers.Q: What types of ink does the machine use and how is ink supplied?

A: The printer uses solvent-based inks, supplied continuously via a negative pressure system. This ensures stable ink flow, prevents interruptions during lengthy print jobs, and helps maintain consistent print quality across various substrates.Q: When should the intelligent drying system be adjusted during printing?

A: The intelligent integrated IR and fan drying system automatically adapts to print conditions. However, users may adjust settings based on media type or environmental humidity to optimize drying efficiency and ink adhesion, especially when switching between different substrates.Q: How does the printer support different software environments?

A: The GZM 3202 Plus is compatible with Maintop, Photoprint, Caldera, and Wasatch RIP software, enabling smooth integration into existing digital print workflows. Multi-language support further enhances usability for operators in India and worldwide.Q: What safety features are included in the printer to protect users and equipment?

A: Safety systems on the machine include overheat protection, an emergency stop button, and a LED status display for real-time monitoring. These features help prevent accidents, safeguard the equipment, and ensure safe operation during continuous large-format production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Solvent Printer Machine Category

Solvent Printer Machine Starfire 1802SG

Price 1500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Features : High Quality

Voltage : 220 Volt (v)

Condition : New

Material : MS

Solvent Printer Machine GZS 3202

Price 1800000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Features : High Quality

Voltage : 220 Volt (v)

Condition : New

Material : MS

Send Inquiry

Send Inquiry