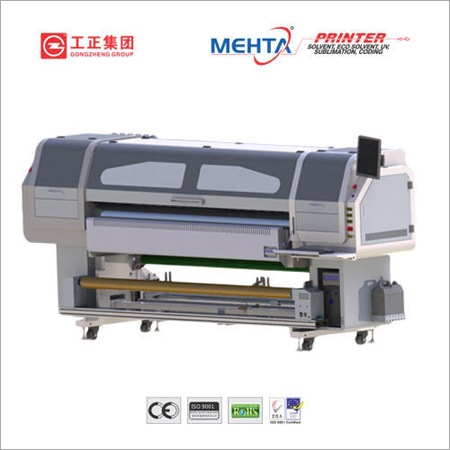

Flex Printer Machine GZE 1802SG

Price 1500000.00 INR/ Unit

Flex Printer Machine GZE 1802SG Specification

- Working Temperature

- 18C - 30C

- Usage & Applications

- Digital flex, advertising, display, event promotion

- Print Speed

- 45-55 sqm/hr

- Noise Level

- 60 dB

- Print Technology

- Piezoelectric inkjet

- Power Supply

- AC single phase

- Processor Speed

- 500 MHz

- Function

- Flex printing

- Capacity

- Continuous printing

- Cabinet Material

- Heavy duty steel

- Processor Type

- Advanced Microcontroller

- Interface

- USB 2.0 / LAN

- Weight

- 255 kg

- Humidity %

- 40-70%

- Features

- High precision printing, stable performance, low maintenance

- Condition

- New

- Material

- Metal frame, industrial components

- Dimensions

- 2780 mm x 800 mm x 1260 mm

- Gross Power

- 850 W

- Voltage

- AC 220V/50Hz

- Automatic Grade

- Semi-Automatic

- Color Print Speed

- Up to 45 sqm/hr

- Black Print Speed

- Up to 55 sqm/hr

- Maximum Paper Size

- 1.8 m wide

- Maximum Resolution

- 1440 dpi

- Use

- Flex printing for advertisement banners, posters, signage

Flex Printer Machine GZE 1802SG Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1 Months

About Flex Printer Machine GZE 1802SG

Product details

| Color Printing | Color Printing |

| Machine Type | Automatic |

| Max Printing Speed (meters/min) | 0-20,20-40,40-60 |

| Max Printing Width | 1000-1500 mm,500-1000 mm,1500-2000 mm |

Technical Specification

| Item | Specification |

| Model | GZE 1802SG |

| Print Head | 2 Starfire 1024 (10pl) |

| Ink | CMYK solvent / eco solvent ink |

| Ink Supply System | GnTek Negative pressure Recirculation system |

| Media Type | Banner, Frontlit, Backlit, Vinyl, Film. |

| Feeding System | Automatic Multiple rolls feeding System |

| Drying System | Pre, mid, post, extended heater plus thermal drying system |

| Printing Speed | 600x400 dpi 96m2 / h |

| Data Interface | External : USB2.0 ; Internal : High-speed SCSI |

| Working Environment | Temp. 23 C ~29 C, Humidity: 50%~80% |

| Software | Photoprint 1/Maintop..... + GZ Control Console |

| Power | 50Hz/AC, 220V10% 15A(printer) + 10A (thermal drying system) |

| Dimension | L x W x H (mm): 3400 x 860 x 1470 |

| G.W. / N.W. | 715kgs / 575 kgs |

Specifications are liable to change without prior notice. All trademarks mentioned are property of their respective owners

Advanced Printing Technology for Professional Results

The GZE 1802SG employs piezoelectric inkjet technology and high-speed Epson printheads, guaranteeing sharp, vivid prints for any advertising material. Its combination of precision feed rollers, 16-bit microprocessor image processing, and capability to handle varied file formats make it ideal for consistent, high-quality output.

Efficient Operation and User-Friendly Features

Equipped with an LCD touch control panel, integrated infrared drying, and automatic safety features, this printer is designed for ease of use and reliable performance. Maintenance tasks such as head cleaning and replacement are streamlined, enabling minimal downtime and optimum productivity on-site.

FAQ's of Flex Printer Machine GZE 1802SG:

Q: How does the Flex Printer Machine GZE 1802SG ensure high precision in printing?

A: The printer utilizes dual high-speed Epson printheads and a 16-bit microprocessor for advanced image processing, along with precision feed rollers to maintain accurate media handling, resulting in high precision and exceptional print quality.Q: What types of media can I use with this printer and what is the maximum thickness?

A: You can print on flex, PVC banners, vinyl, and mesh media with a maximum thickness of 1 mm, making the GZE 1802SG versatile for various advertising applications.Q: When is it recommended to perform head cleaning, and how is the maintenance process managed?

A: Head cleaning should be performed when print quality decreases or as part of routine maintenance. The GZE 1802SG features an easy head cleaning and replacement design, minimizing service time and effort.Q: Where can the GZE 1802SG be set up for optimal operation and storage?

A: It should be installed in environments with a controlled temperature (18C - 30C) and humidity (40-70%), ideally in professional printing studios or workshops with sufficient space for its dimensions and proper ventilation.Q: What is the process for connecting and operating the printer with supported software?

A: Connect the printer using Ethernet or USB interfaces, then utilize Photoprint or Maintop rip software to process files in BMP, TIFF, JPEG, PNG, or PDF formats, ensuring smooth, automated printing and color management.Q: How does the integrated infrared drying system benefit the printing workflow?

A: The infrared drying system accelerates ink curing, allowing for continuous printing at high speeds without smudging, and supports uninterrupted production for large batches of advertising materials.Q: What primary advantages does using the GZE 1802SG offer for commercial printing businesses?

A: Its high-speed output, stable performance, compatibility with diverse media, and low maintenance requirements provide businesses with efficient production, reduced operational costs, and reliable quality for advertising and display needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Flex Printer Machine Category

Flex Printer Machine GZS 3202

Price 1800000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Voltage : 220V/50Hz

Automatic Grade : Automatic

Use : Advertising and promotional printing

Condition : New

Flex Printer Machine Thunder Jet C1601

Price 465000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Voltage : AC 220V, 50/60Hz

Automatic Grade : Automatic

Use : Flex Printing

Condition : New

Flex Printer Machine Starfire GZC 3202

Price 1100000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Voltage : AC 220 V 10%, 50/60 Hz

Automatic Grade : Automatic

Use : Flex printing

Condition : New

Banner Printing Machine

Price 1150000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Voltage : 220V / 110V, 5060Hz

Automatic Grade : SemiAutomatic

Use : Commercial Banner Printing

Condition : New

Send Inquiry

Send Inquiry