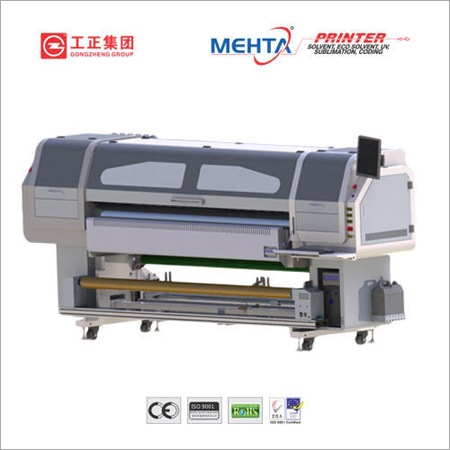

Flex Printer Machine Thunder Jet C1601

Price 465000.00 INR/ Unit

Flex Printer Machine Thunder Jet C1601 Specification

- Processor Speed

- High performance industrial processor

- Print Speed

- 18-20 sqm/hr

- Features

- High speed printing, Easy maintenance, Precise color reproduction

- Function

- Print only

- Power Supply

- AC Input

- Noise Level

- <70 dB

- Capacity

- Continuous Roll Feed

- Print Technology

- Piezoelectric Inkjet

- Interface

- USB 2.0 High-Speed

- Usage & Applications

- Advertising Materials, Billboard, Banners

- Processor Type

- Industrial grade control board

- Working Temperature

- 15-30

- Weight

- 230 kg

- Humidity %

- 35-65% RH

- Cabinet Material

- Powder coated metal

- Condition

- New

- Material

- Steel Frame, Aluminium Parts

- Dimensions

- 2500 x 800 x 1200 mm

- Gross Power

- 500 Watt

- Voltage

- AC 220V, 50/60Hz

- Automatic Grade

- Automatic

- Color Print Speed

- 18-20 sqm/hr

- Black Print Speed

- 20 sqm/hr

- Maximum Paper Size

- 1600 mm

- Maximum Resolution

- 1440 dpi

- Use

- Flex Printing

Flex Printer Machine Thunder Jet C1601 Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1 Months

About Flex Printer Machine Thunder Jet C1601

Product details

| Type | Digital printer |

| Color Printing | Yes |

| Machine Type | Automatic |

| Max Printing Width | >2500 mm |

Technical Specification

| Model

| ThunderJet C1601 |

| Print Head

| One Epson DX5 Print head |

| Technology

| Piezo Variable dot (Greyscale) |

| Ink

| C.M.Y.K Eco solvent ink (2 years outdoor durability) |

| Printing Width

| Max. 1520mm |

| Media Type

| Coated PP, Vinyl, Film, Banner...... |

| Printing Speed | Draft 17.7m2 /hr Production 13.3 m2 /hr High-res 9.7m2 /hr Photo 8.2m2 /hr |

| Data Interface

| External : USB2.0+; Internal: High-speed SCSI |

| Working Environment

| Temp.23???~29???, Humidity:50%~80% |

| Software

| PhotoPRINT/Maintop......+ThunderJet control console |

| Power

| 50Hz/AC,220V+10% 3A(printer)+10A(IR drying system) |

| Dimension

| LxWxH(mm):2718x780x1442 |

Efficient High-Speed Printing

Engineered to deliver remarkable print speeds of 18-20 square meters per hour for color, the Thunder Jet C1601 streamlines large-scale printing tasks. Its automatic feed system and high-performance processor handle continuous roll printing with consistent output quality and minimal interruption. The integrated heater drying system further accelerates production, drying prints fast while maintaining vibrant coloration.

Advanced Technology for Precision Output

Utilizing Piezoelectric Inkjet technology, the C1601 achieves precise color reproduction at resolutions up to 1440 dpi. The industrial control board optimizes workflow and ensures reliable operation. Its digital LCD touch panel allows seamless navigation and intuitive machine control, while voltage protection safeguards against power fluctuations, maximizing uptime and print consistency across operations.

Ease of Use and Maintenance

Designed for automatic operation and simple maintenance, the Thunder Jet C1601 features an automatic head cleaning system and digital interface for straightforward monitoring. Users benefit from easy media loading and minimal downtime. The sturdy steel frame and powder-coated cabinet add to its reliability, and clear control options through the LCD panel make day-to-day operation hassle-free even in demanding environments.

FAQ's of Flex Printer Machine Thunder Jet C1601:

Q: How does the Flex Printer Machine Thunder Jet C1601 benefit my advertising business?

A: The Thunder Jet C1601 delivers high-speed, precise color printing, making it ideal for producing vivid banners, billboards, and other promotional materials efficiently. Its seamless workflow, reliable performance, and compatibility with industry-standard software help streamline production and lower operational costs.Q: What file formats and software does this printer support?

A: The C1601 is compatible with TIFF, JPEG, BMP, and PNG file formats, and it works with leading printing software such as Photoprint, Maintop, and Wasatch, ensuring flexibility for diverse printing requirements and easy integration into existing workflows.Q: When is routine maintenance required and how is it performed?

A: Routine maintenance is simplified due to the printer's automatic head cleaning system. Maintenance frequency depends on print volume, but the digital LCD touch panel guides users through cleaning and monitoring processes to prevent clogging and preserve print quality.Q: Where is this printer suitable for use?

A: The Thunder Jet C1601 is suitable for use in advertising agencies, printing shops, and manufacturers needing high-quality flex printing for applications such as billboards, banners, and other outdoor promotional materials. It is designed to operate in environments with 35-65% relative humidity and a temperature range of 15C to 30C.Q: What is the process for printing large rolls of material?

A: Users simply load the roll material, ensuring the diameter does not exceed 200 mm. The printer's continuous roll feed and integrated heater drying system maintain efficient and consistent output. Print speed ranges from 18-20 sqm/hr for color and up to 20 sqm/hr for black, accommodating large print jobs with ease.Q: How does the voltage fluctuation protection work?

A: The built-in voltage fluctuation protection helps safeguard the printer's electronics against sudden power changes, thereby enhancing reliability and reducing risks of equipment failure or print defects, especially in environments with unstable electricity supply.Q: What materials and conditions are required for optimal operation?

A: Optimal operation requires media with thickness up to 2 mm, a maximum roll diameter of 200 mm, and an environment within 35-65% humidity and 15C-30C temperature. The printer's steel frame and aluminium parts add durability, making it suitable for continuous industrial printing tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Flex Printer Machine Category

Flex Printer Machine GZS 3202

Price 1800000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Material : Heavyduty Metal

Condition : New

Automatic Grade : Automatic

Use : Advertising and promotional printing

Flex Printer Machine Starfire GZC 3202

Price 1100000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Material : Steel, Aluminum

Condition : New

Automatic Grade : Automatic

Use : Flex printing

Flex Printer Machine GZE 1802SG

Price 1500000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Material : Metal frame, industrial components

Condition : New

Automatic Grade : SemiAutomatic

Use : Flex printing for advertisement banners, posters, signage

Banner Printing Machine

Price 1150000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Material : Metal and ABS Cabinet

Condition : New

Automatic Grade : SemiAutomatic

Use : Commercial Banner Printing

Send Inquiry

Send Inquiry