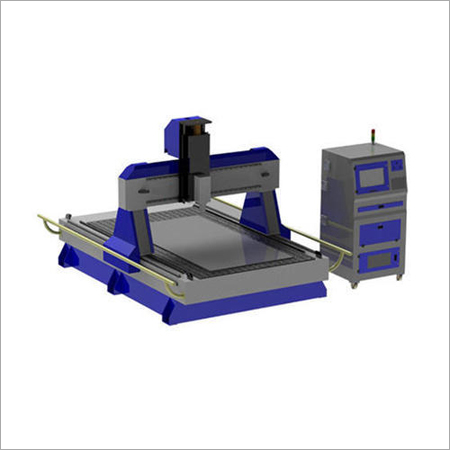

CNC Stone Carving Machine

Price 750000.00 INR/ Unit

CNC Stone Carving Machine Specification

- Noise Level

- <80 dB

- Motor Power

- 3.0-5.5 kW spindle

- Frequency

- 50/60 Hz

- Control System

- DSP Controller/NC Studio

- Production Capacity

- Up to 120 sqm/day

- Voltage

- 380V/50Hz

- Lubricating System

- Automatic Lubrication

- Power Rating

- 4.5 kW

- Features

- Sturdy structure, high precision, stable operation

- Drive

- Stepper/Servo Motor

- Operating Temperature

- 5C - 40C

- Cooling System

- Water Cooling

- Accuracy

- 0.05 mm

- Connectivity Options

- USB connectivity, offline controller

- Machine Type

- CNC Stone Carving

- Model No

- SCM-1325

- Frame Type

- Heavy Duty Welded Frame

- Product Type

- CNC Stone Carving Machine

- Technology

- CNC (Computer Numerical Control)

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 4.5 kW

- Pressure

- Adjustable, typically 0.5-2.0 MPa

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 3200x2200x1800 mm

- Weight (kg)

- 2100 kg

- Color

- Blue & Silver

- Usage & Applications

- Engraving, Carving, Cutting marble, granite, and other stones

- Rail Type

- Linear Square Guide Rail

- Environment Humidity

- <85% non-condensing

- Software Compatibility

- ArtCAM, Type3, Ucancam, JD Paint

- Table Structure

- Vacuum Table with T-slot

- Input Method

- USB port, Ethernet (optional)

- Spindle Speed

- 0-24000 rpm

- Transmission

- Rack and Pinion for X/Y axis, Ball Screw for Z axis

- Compatible File Formats

- G-code, HPGL, DXF

- Max Processing Thickness

- 200 mm

- Safety Features

- Emergency stop, safety covers, overload protection

- Working Speed

- 6000 mm/min

- Max Travelling Speed

- 12000 mm/min

CNC Stone Carving Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1 Months

About CNC Stone Carving Machine

Mehta Cad Cam Systems Pvt Ltd is a big name that deals in the manufacturing and supplying of CNC Stone Carving Machine that is specially designed for designer stone making industries. It is installed with high-performance drives that make it capable to operate efficiently for a longer period without any risk of damages. This semi-automated unit provides a large machining area of 1300 x 2500 millimeters that making it highly demanding and popular among our customers. Customers can get this CNC Stone Carving Machine from us as per their demands at a reasonable price range.

Product details

| Applicable Materials | COPPER, BRASS |

| Brand | Mehta |

| Production Capacity | 10000 pieces per day |

| Automation Grade | Semi-Automatic |

| Phase | 3 |

Technical Specification

| Model | STONA 1325 | STONA 1530 |

| Outer Dimension(W x L x H) | 2365 x 3630 x 1575 mm | 2565 x 3830 x 1575 mm |

| Machining Area | 1300 x 2500 mm | 1300 x 2500 mm |

| Spindle | 5.5 KW (Water cooled spindle) | 5.5 KW (Water cooled spindle) |

| Spindle RPM | 24000 max | 24000 max |

| Z Max. Traveling | 300 mm | 300 mm |

| Distance between Bed and Gentry | 300 mm | 300 mm |

| Cutting Tool Diameter | Ø3, Ø4, Ø6, Ø8, Ø10 | Ø3, Ø4, Ø6, Ø8, Ø10 |

| Repeated Location | 0.025 mm | 0.025 mm |

| Max Running Speed | 15 m/min | 15 m/min |

| Weight | 1070 Kg | 1575 Kg |

| Power Supply | AC 420V / 50Hz | AC 420V / 50Hz |

Precision and Efficiency

The SCM-1325 CNC Stone Carving Machine ensures impeccable detail with its high spindle speed and advanced control system. Its rack and pinion transmission for X/Y axes and ball screw for the Z axis facilitate smooth and accurate movements, even during high-speed operations. The automatic lubricating system further enhances reliability, reducing maintenance time and increasing output efficiency.

Robust Engineering

Built on a heavy-duty welded frame, the machine can withstand continuous industrial use. The linear square guide rails, water cooling system, and powder-coated surface guard against wear, keeping operations stable in demanding environments. Adjustable pressure settings and well-designed emergency features add to its safe and dependable performance.

Versatile Application

Compatible with popular design software and accepting multiple file formats, the SCM-1325 is ideal for a variety of stone processing tasks-engraving, carving, and cutting. Whether used in a manufacturing plant, workshop, or design studio, it delivers consistent quality for both simple and intricate stone projects, supporting up to 120 square meters of production per day.

FAQ's of CNC Stone Carving Machine:

Q: How do I set up compatible files for engraving and carving on this CNC Stone Carving Machine?

A: You can prepare designs using software such as ArtCAM, Type3, Ucancam, or JD Paint. Save your project in supported file formats like G-code, HPGL, or DXF, which can then be uploaded via the USB port or Ethernet connection for processing.Q: What safety features are included with the SCM-1325 CNC Stone Carving Machine?

A: The machine is equipped with an emergency stop button, safety covers, and overload protection to minimize risks during operation, ensuring a safe working environment for the operator.Q: When is this machine suitable for use, and what types of stones can it process?

A: The CNC Stone Carving Machine is suitable for use in environments where precision carving, engraving, and cutting of marble, granite, and similar stones are required. It operates optimally between 5C and 40C with less than 85% non-condensing humidity.Q: Where can the CNC Stone Carving Machine SCM-1325 be installed?

A: The machine is designed for installation in industrial workshops, manufacturing units, and professional stone processing facilities in India or other similar environments that provide the necessary power and space requirements.Q: What is the process for routine maintenance?

A: Routine maintenance is simplified by the automatic lubrication system, keeping critical moving components operating smoothly. Regular cleaning and water cooling checks are also recommended for optimal performance.Q: How does using the vacuum table with T-slot benefit my operations?

A: The vacuum table ensures firm and stable fixation of stone pieces during machining, while T-slots enhance flexibility for custom setups-reducing vibration and improving carving precision and safety.Q: What are the benefits of using the SCM-1325 for stone fabrication?

A: Key benefits include high processing capacity (up to 120 sqm/day), precise results (accuracy 0.05 mm), robust durability, versatility in compatible software, enhanced safety protocols, and minimal noise (<80 dB) for a professional working environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Carving Machine Category

3D Wood Carving Machine

Price 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other, Paint Coated

Color : Blue & White

Usage & Applications : Wooden furniture, MDF panels, signage, decorative panels, intricate wood designs

Power Source : Other, Electric

CNC Wooden Pattern Making Machine

Price 1500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Painted

Color : Blue & Grey

Usage & Applications : Industrial

Power Source : Electricity

Send Inquiry

Send Inquiry